1. First wet the ground base with clean water, and only when there is no clear water on the surface can it be used as a binder.

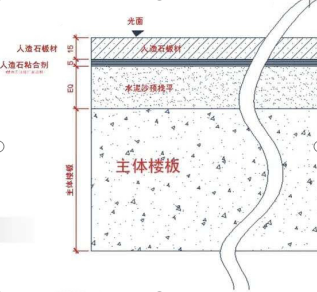

2. Confirm that there is no clear water on the base surface, batch scraping special artificial stone adhesive (strip shape/full batch scraping) thickness of more than 3mm, the same practice on the back of the stone, the thickness is 2-3mm, and then paste the stone.

3. After pasting the stone within the specified time (according to the requirements of the adhesive product instructions), after laying the stone, gently tap it with a mallet so that the newly pasted artificial stone can be completely closely fitted with the adhesive.

4. Correct the seam between the horizontal and the adjacent plate, and pay attention to the seam between the stones of 2mm or more.

5. After 3 days of pasted stone (according to the instructions for use of special artificial stone adhesive), the seam can be cleared and caulking, and special artificial stone caulk should be used when closing the seam.

6. Clean after caulking treatment (cannot use acid-containing and alkaline cleaning agents, it is recommended to use special artificial stone cleaning agents) caulks and dirt attached to the surface of the plate.

7. Note: When paving a large area, 5-8mm expansion joints should be set at an appropriate interval of 8-10 meters.

8. After the stone is laid, the film is torn open after acceptance and cleaning.